Microfiltration (MF) for Legionella and Water Borne Pathogens Control

What is microfiltration Legionella control and how does it compare to ultrafiltration, nanofiltration and reverse osmosis?

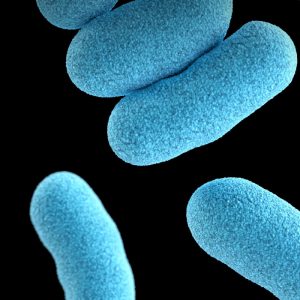

Microfiltration is a cost-effective way to help prevent the spread of Legionella and prevent Legionaries disease. Legionella, like other harmful bacteria are larger than .22 micron. With a .2 or .1 micron Legionella microfiltration system, you can filter out bacteria as it cannot fit through the pores of the filter.

Microfiltration is a cost-effective way to help prevent the spread of Legionella and prevent Legionaries disease. Legionella, like other harmful bacteria are larger than .22 micron. With a .2 or .1 micron Legionella microfiltration system, you can filter out bacteria as it cannot fit through the pores of the filter.

The main difference between microfiltration and RO, UF, NF is pore size. Microfiltration will remove everything .1 micron and larger from the water including bacteria. While the other systems remove smaller particles and even molecules from the water, more energy and water pressure needed for the processes. Most microfiltration systems do not have any sort of crossflow or water going to the drain so they are quite efficient. You can run a microfiltration system on low pressure and low energy. As you move up through the filtration types: ultra, nano, RO, the pore size decreases which requires higher osmotic pressure and energy needed to create the permeate (clean) water. View the full breakdown of particle sizes and pathogen control applications>.

Microfiltration is a preferred method of Legionella control for many hospitals, healthcare facilities, community and municipal water treatment systems. This is due to its ability to reliably and affordably remove Legionella and an array of water borne pathogens while operating with lower water pressures and little to no water loss saving energy and reducing costs.

How is Legionella removed with microfiltration?

Legionella can be removed with microfiltration as long as the filter size is .2 micron or less. The principle of micro filtration is physical separation. The extent to which bacteria, such as Legionella and other pathogens, are removed is determined by the size of the pores in the membranes. Membranes with a pore size of 0.1 – 10 µm (microns) perform micro filtration. Bacteria and viruses that are larger than the pores in the membranes are removed. On a cautionary note, most microfiltration systems are not absolute, meaning they will not filter out 100% of particles smaller than the pore size.

Legionella can be removed with microfiltration as long as the filter size is .2 micron or less. The principle of micro filtration is physical separation. The extent to which bacteria, such as Legionella and other pathogens, are removed is determined by the size of the pores in the membranes. Membranes with a pore size of 0.1 – 10 µm (microns) perform micro filtration. Bacteria and viruses that are larger than the pores in the membranes are removed. On a cautionary note, most microfiltration systems are not absolute, meaning they will not filter out 100% of particles smaller than the pore size.

Substances that are smaller than the pores of the membranes are partially removed, depending on the construction of a refuse layer on the membrane. Microfiltration membranes remove the majority of bacteria, including Legionella. Only part of the viral contamination is caught up in the process because viruses are smaller than the pores of a micro filtration system. Viruses can attach themselves to bacterial biofilm and are filtered out in this case. Micro filtration can be implemented in many different water treatment processes when particles with a diameter greater than 0.1 microns need to be removed from a liquid. Pairing a Microfiltration system with an Ultraviolet (UV) Treatment Systems will increase the effectiveness in removing viruses (for example, Enteric, Hepatitis A, Norovirus, Rotavirus). Many UV systems require a 5 micron or smaller microfiltration system to be installed upstream to increase UV efficacy.

Microfiltration as a pretreatment for RO and UV:

- RO systems- The bulk of cost on RO systems is in the pump and the membranes. Anything you can do to extend the life of both will save you exponentially on expenses. The more suspended solids (TSS) we can remove from the system the smaller the chance for fouling on the RO membranes. Since microfiltration has a high recovery rate it is a solid way to pretreat for the RO while maintaining good water pressure.

- UV systems- UV systems effectiveness is based on the UV lights ability to transmit through the water. This can be affected by turbidity (cloudiness), suspended solids (TSS) hardness scaling or staining on the quartz sleeve. The better the water entering the microfiltration system, the longer the system will be able to run effectively without maintenance.

Microfiltration effects on Disinfectants:

Microfiltration greatly improves the effectiveness of your disinfectant treatments because it removes 99.99% of organic particles. Removing these particles from the water before the disinfectant is introduced leaves more of the disinfectant to act upon the pathogens and not consume by organic particles.

Sizing your Legionella Control Microfiltration System:

Legionella Control Microfiltration (SF) Systems are sized using water chemistry, suspended solids (TSS), pH, turbidity and temperature. Once the variables of the water are known, the flux (volume per area per unit of time) can be calculated. With this information, the size and amount Micro filters can be designed.

Often times, it makes sense to have a series of microfilters to control Legionella. If the water has a high amount of suspended solids that are of a larger size, it is prudent to have a 5 or 10 micron filter ahead of the .1 or .2 micron filter to make the system more efficient. For potable and domestic water uses that are not treated with a reverse osmosis or nanofiltration system, a water analysis of particle size should be performed.

Industrial Water Legionella Control Microfiltration System Service, Design and Sales

Contact us at info@legionellacontrolsystems.com or 888-416-8626 for sizing, sales, leasing and service of Microfiltration systems in Indiana, the Midwest and throughout the U.S. for your MF system and Legionella Control water systems. Our experienced engineers are ready to help.

Contact Legionella Control Systems for CDC Legionella risk assessment and Legionella testing.